A Global MES

Annual license per plant, unlimited users

We focus on creating tailored solutions for your company’s digital transformation, helping you take the next step toward Industry 4.0 in a seamless, gradual, and flexible way.

Our approach is designed to meet your unique needs and budget, ensuring a smooth transition to the latest technologies that will drive your business forward.

High Quality Software

Our Manufacturing Systems are designed with the highest industrial standard and competitive price.

Secure and Reliable

With regular updates and robust fail-safe mechanisms, our software provides dependable security and operational reliability, making it a trusted solution for businesses.

Manufacturing Processes Automation

Our products help industries reduce overhead costs, improve JIT delivery, and mantain low inventory stocks with whole-line tracking for quality and quantity control.

The Solution SmartSuite

Increased productivity

Cost reduction

Efficiency and record times

Our Products

SmartSuite

SmartSuite is a whole package of solutions integrated by modules to ensure a robust, efficient and secure process from the reception of the raw material, through the production lines, to the packaging and shipment of the finished goods.

However, our software is made in such way that it can be implemented by specific module based on each customer needs.

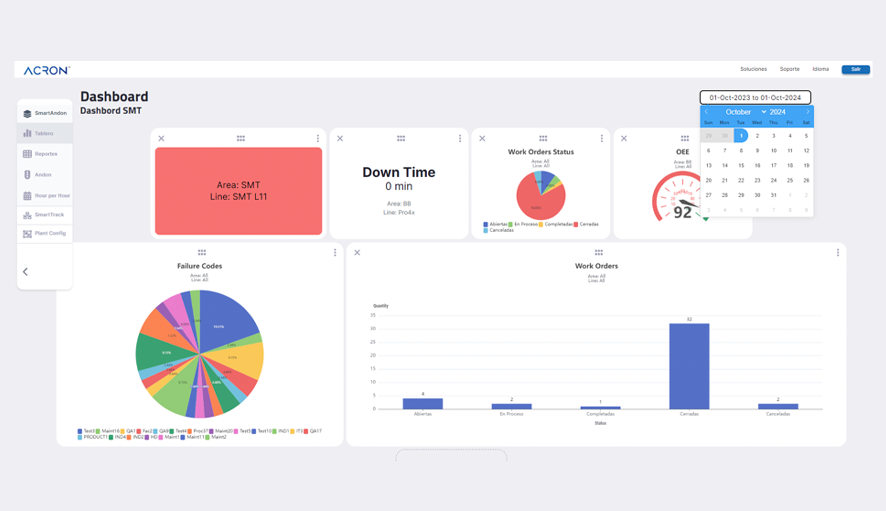

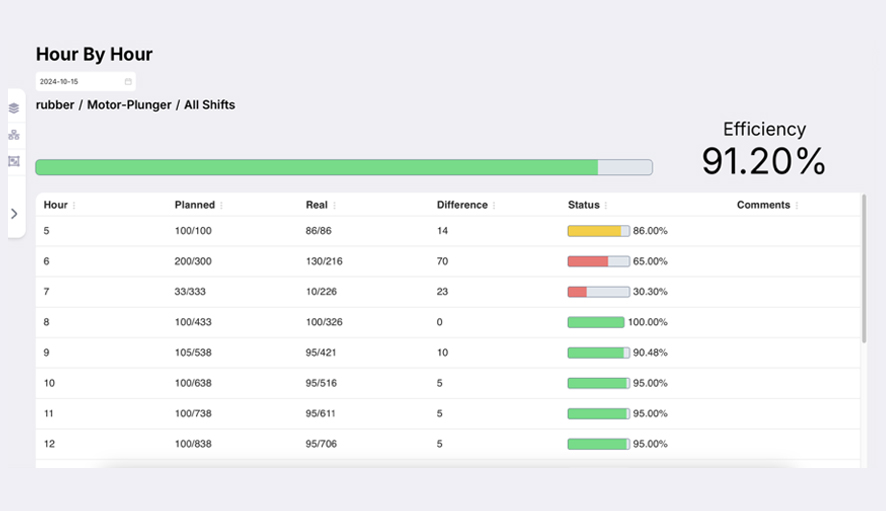

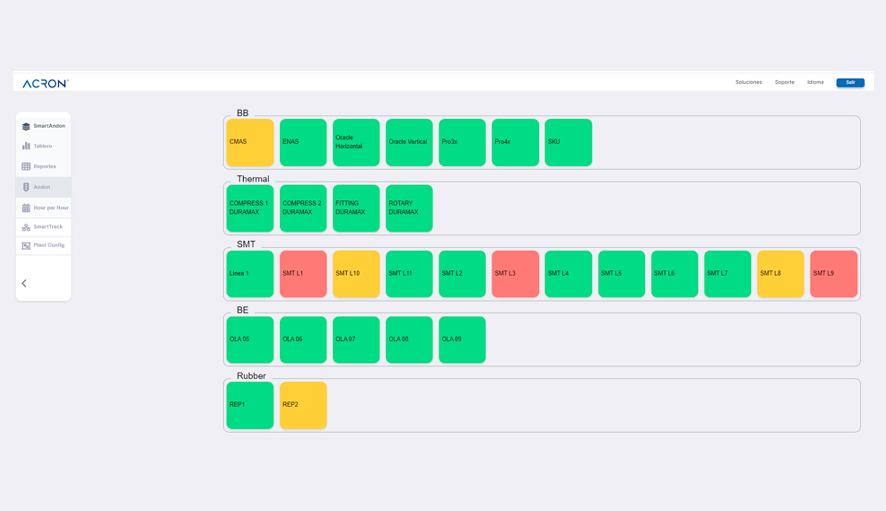

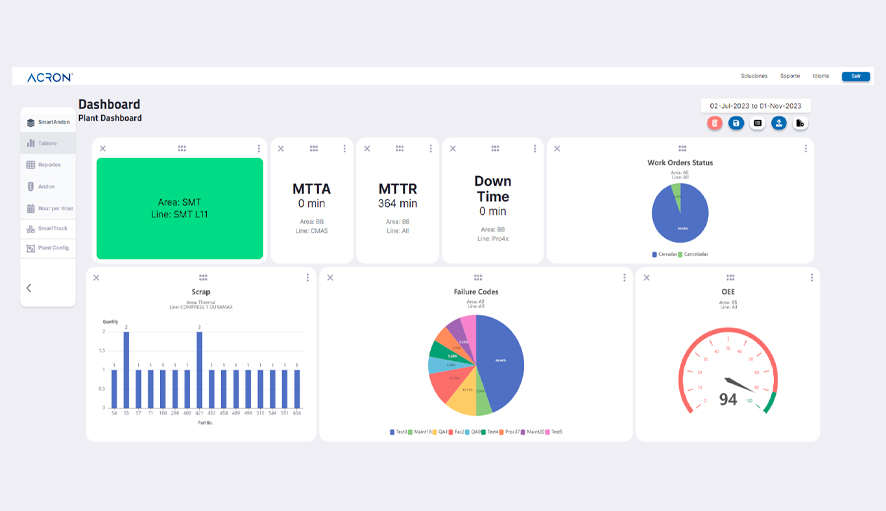

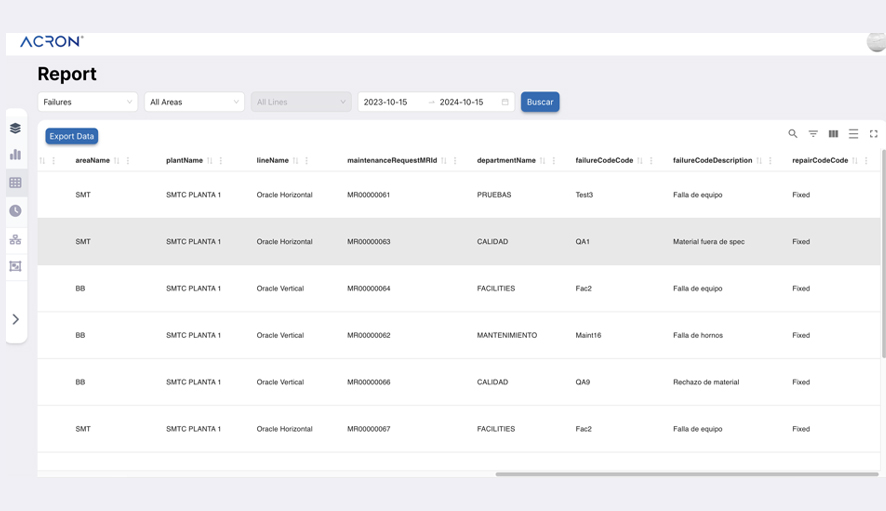

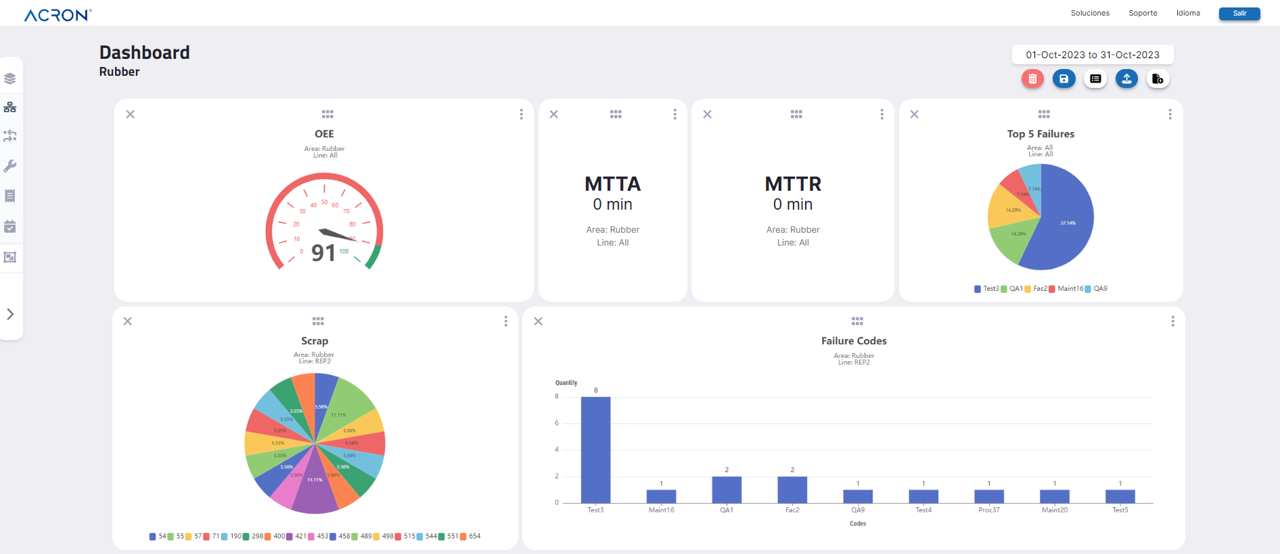

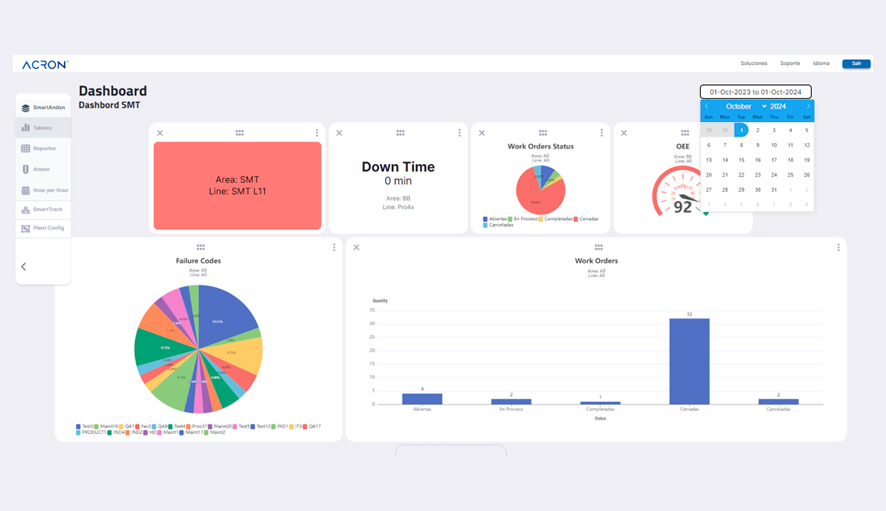

SmartAndon

Key Performance Indicators module interacts with each of Acron modules to design and present extensive reports needed for analytics, it also covers real-time Dashboards and Alert functions.

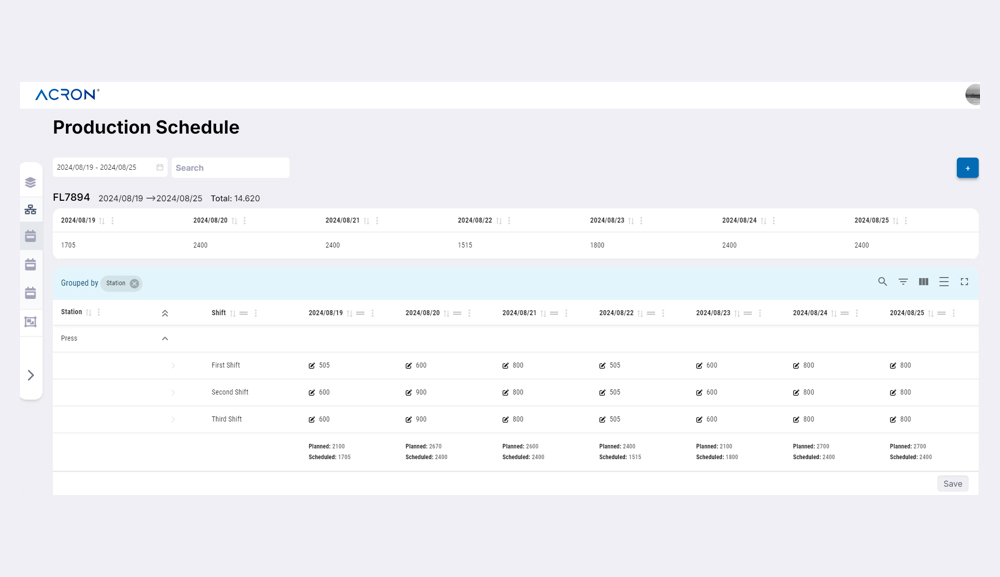

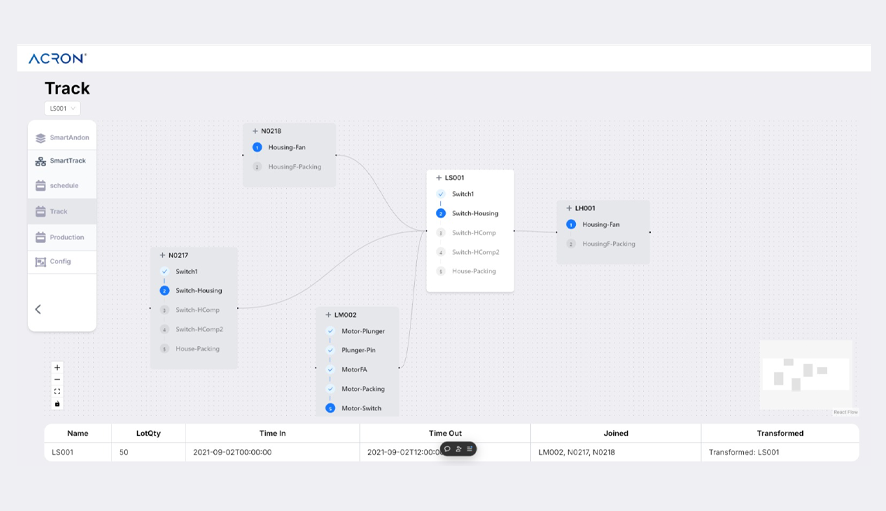

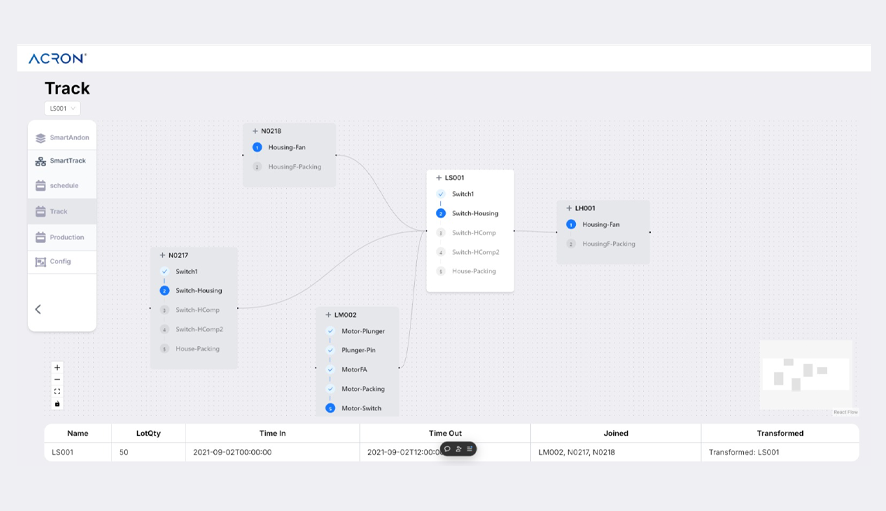

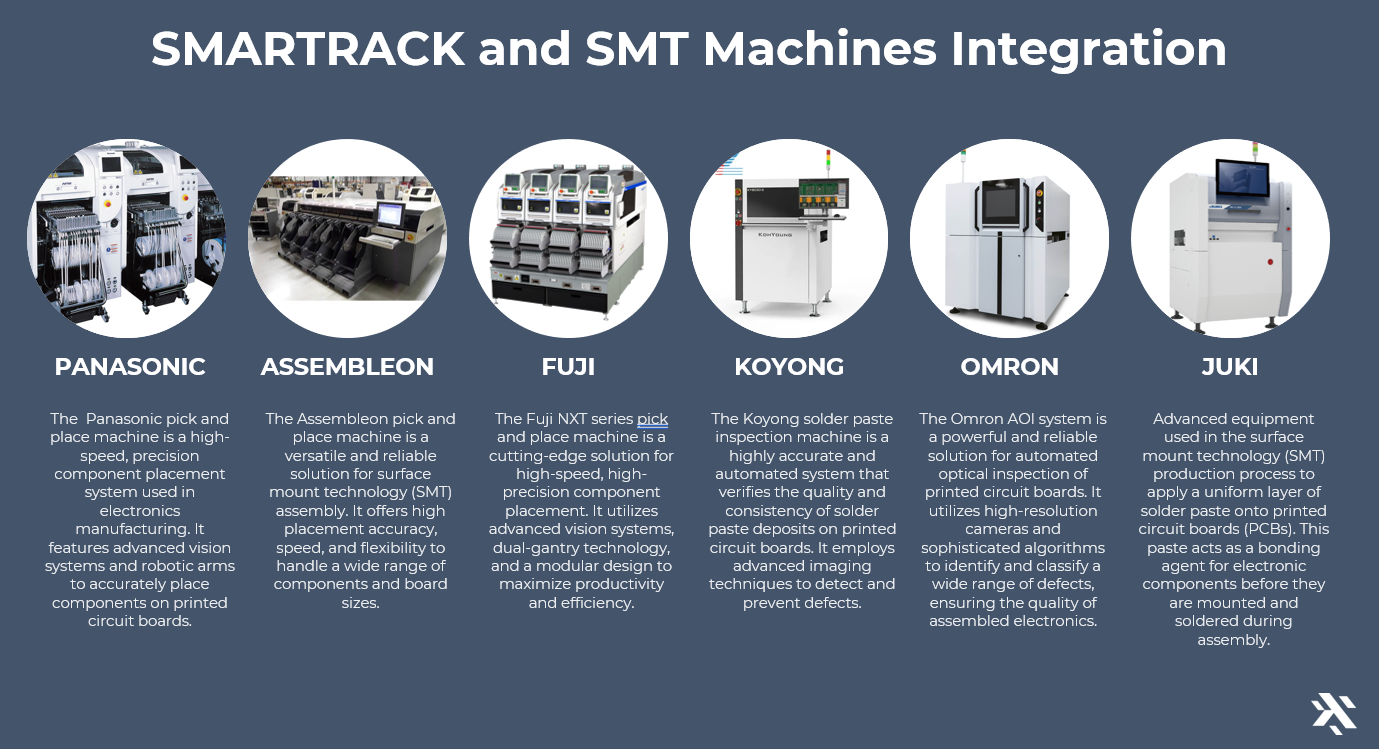

SmarTrack

Smart Track System is an extensive module for tracking and monitoring every step of the manufacturing process. It helps ensure product quality, identify issues quickly by providing realtime data on materials, components, and production stages.

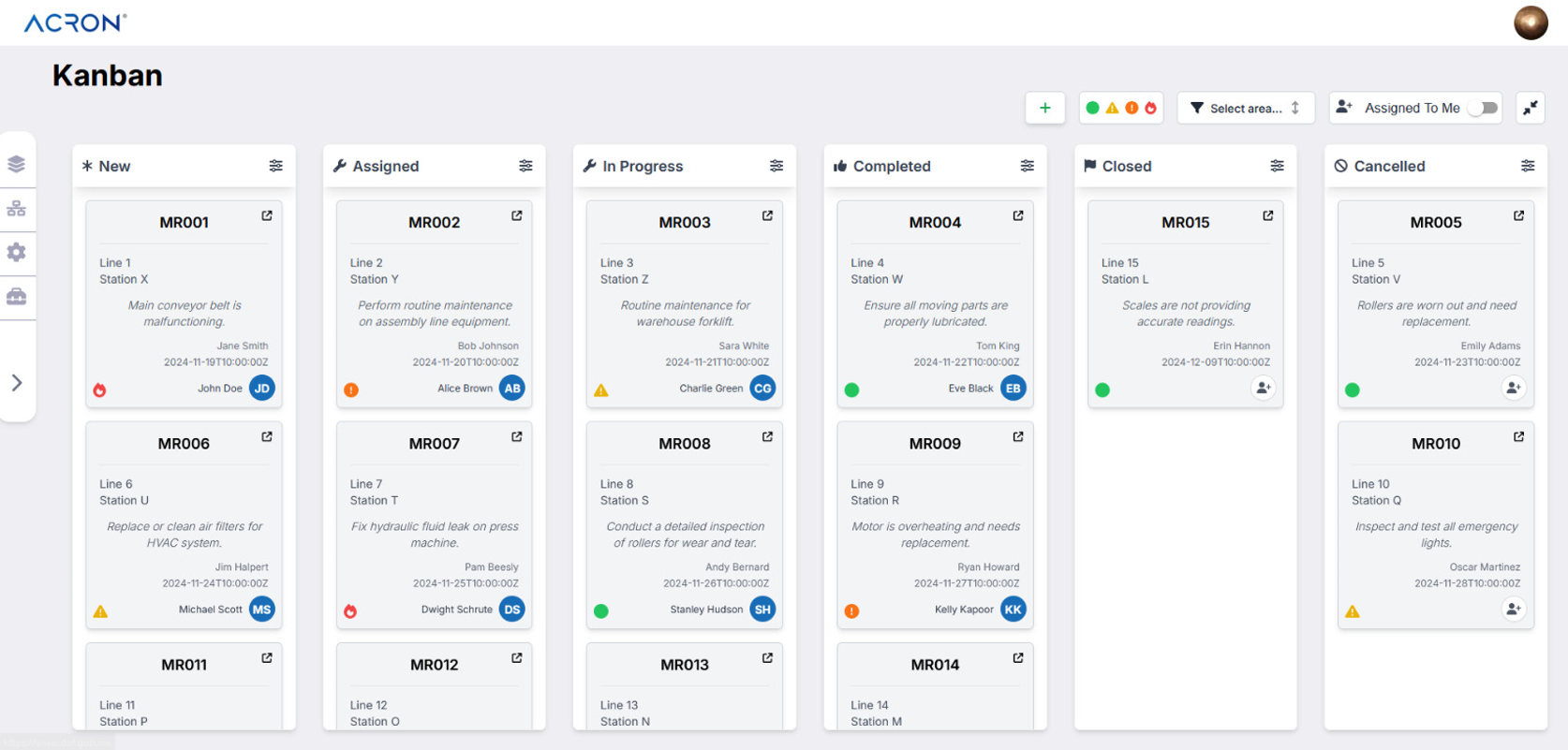

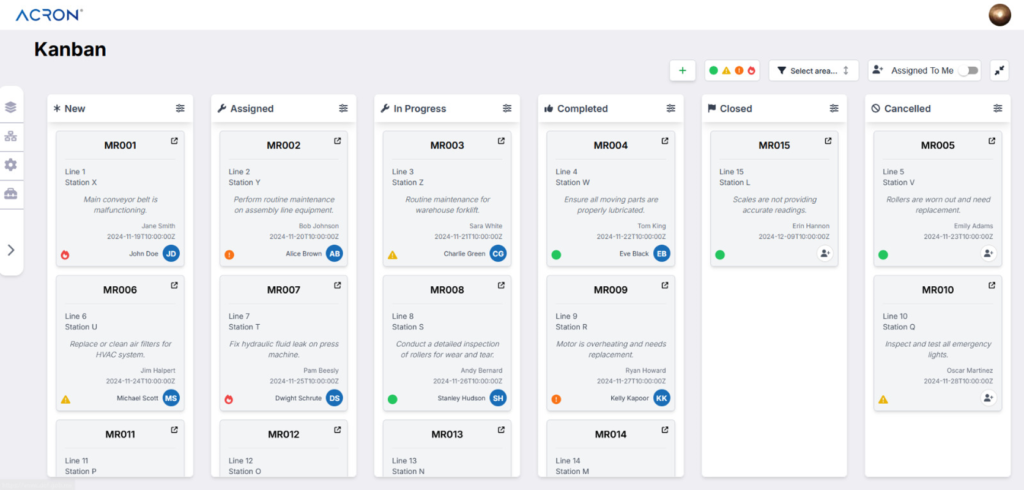

SmartMaint

Smart Maintenance is an extensive module for all maintenance related activities . It helps to maximize equipment efficiency, minimize downtime, improve productivity and reduce operational costs.

SmartWMS

Smart Warehouse Management System is a

comprehensive solution for all operational needs in a

warehouse from material reception through line feed.

It can also quarantine bas quality suspicious material

to a specific area.

This module is capable to interact with

a local ERP system.

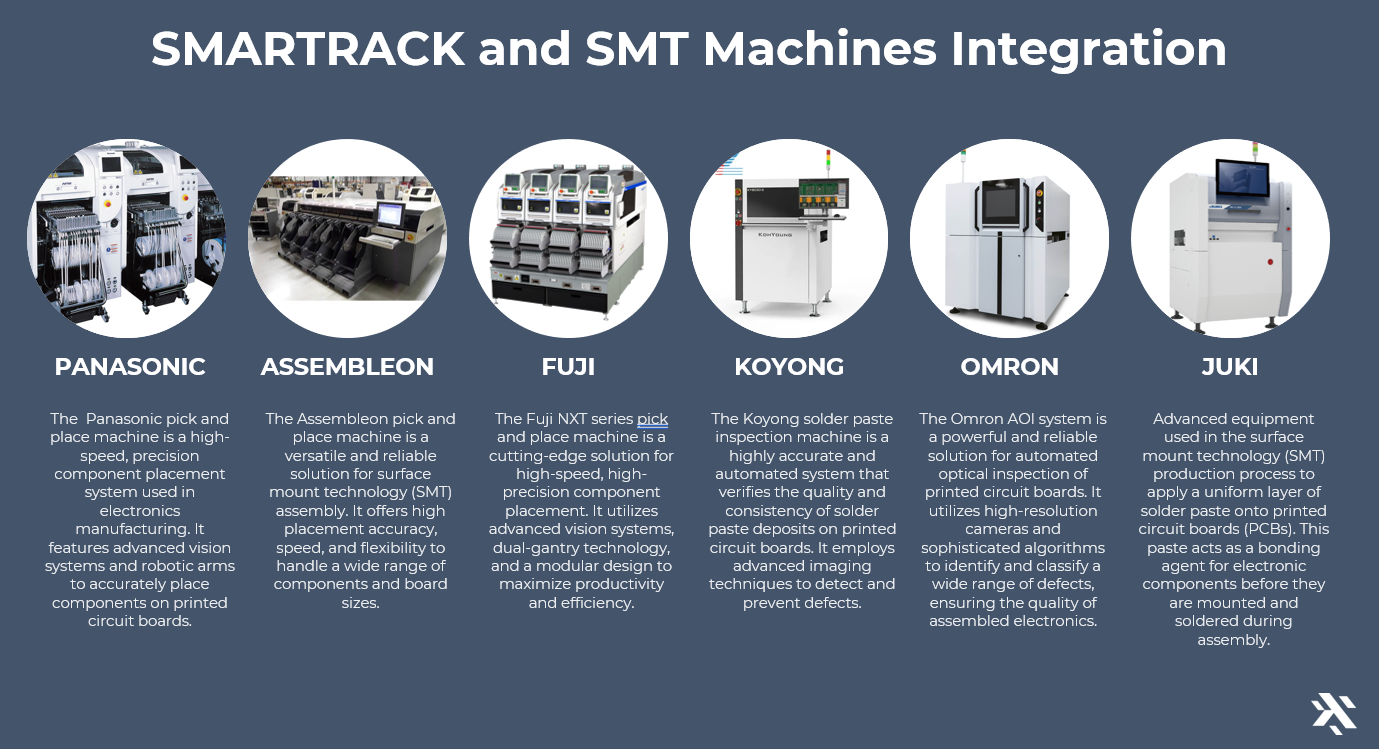

Machine Integration

Our MES includes the necessary interfaces for seamless communication with various equipment.

All package of solutions integrated by modules to ensure a robust, efficient and secure process from reception of the raw material, through the production lines, to the packaging and shipment of the finished goods.

However, our software is made in such way that it can be implemented by specific module based on each customer needs.

Application in small, medium, and large industries

Industries

Our Services

Analysis and Diagnosis

We thoroughly analyze your company’s current system to identify weak points that need improvement, allowing us to implement the appropriate solution for your existing equipment.

Implementation and Training

Installation of SmartSuite with all necessary configurations and adaptations to your system, along with training for your team of engineers, technicians, and support staff. We provide indicators to ensure continuous monitoring at every stage.

24/7 Support

Understanding the critical nature of manufacturing, we offer support for different production shifts based on each client’s needs and defined SLAs.

Testimonials

What Clients Say

Achievements, Events and Certifications

We use cutting-edge technology to create solutions tailored to your needs.

MES

Manufacturing Execution Systems

IIOT

Internet Industrial Of Things

IA

Artificial Intelligence

ML

Machine Learning

Schedule A Demo

Discover how our solutions can optimize your operations. Schedule a demo today and see firsthand how we can help you drive efficiency and growth.